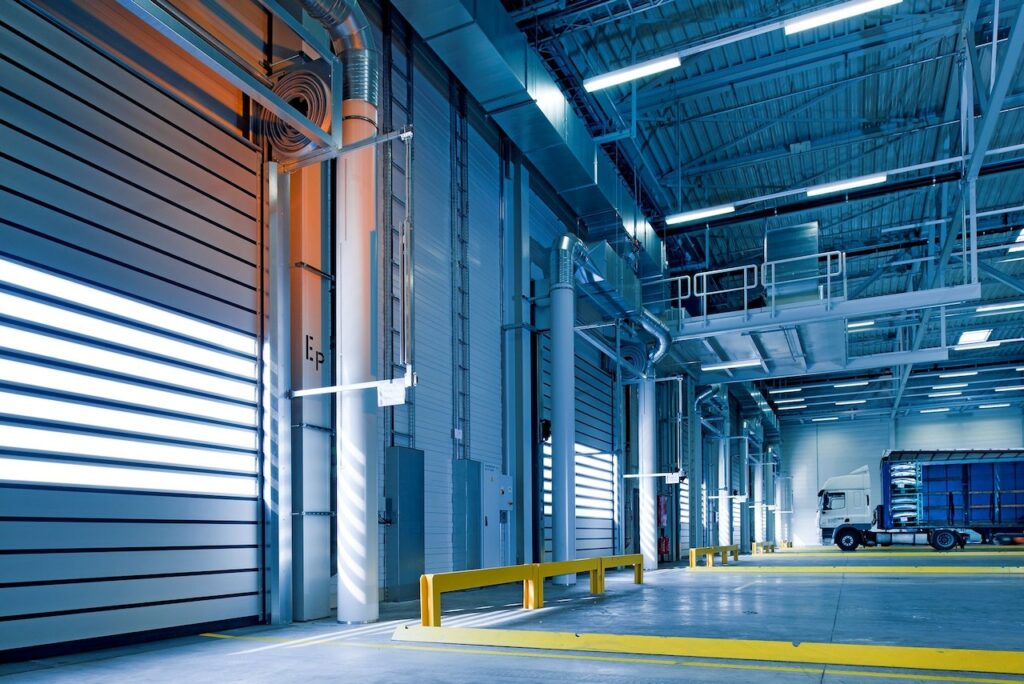

Knowing the different types of loading docks is crucial, whether an individual is looking forward to opening his warehouse or improving his distribution process. A loading dock is a specific area in a warehouse or distribution center utilized to load and unload goods. They are one of the essential aspects of a business’s infrastructure and contribute greatly to the transportation of goods. Choosing the wrong storage with loading dock can negatively impact the staff, causing disruptions in the shipping and receiving processes. Go through this article to learn about different types of warehouse loading docks.

Flush Dock

A flush dock, or standard dock, is one of the most popular loading docks. These docks are designed in such a way that they can fit perfectly within the loading zone. Because of their large, individual entryways, it becomes seamless for the trucks to attach for loading. Moreover, flush docks often feature shock-absorbing bumpers to prevent structural damage to the facility.

Now that flush docks don’t protrude from the building, business owners can make the most of warehouse storage with loading dock. Furthermore, flush docks are built into the facility, allowing the storage of the goods inside and protecting them from the elements.

Sawtooth Dock

The Sawtooth loading dock consists of multiple smaller docks, each positioned at a certain angle. These docks help companies save space outside their facilities while allowing the loading of more vehicles at a time. Moreover, the sawtooth loading dock simplifies the roadway and yard approaches, allowing vehicles to navigate narrow spaces easily. These loading docks are often used in large-scale manufacturing units or in hugely spacious warehouses.

Enclosed Dock

An enclosed loading dock is a perfect choice when parking an entire vehicle in a garage-like environment. Since these loading docks are built indoors, they offer complete protection to the goods against the elements and are ideal for storing temperature-sensitive products. In addition, these docks allow for increased security compared to other loading docks.

Although enclosed loading docks are relatively rarely utilized in the warehousing industry, they are the perfect choice for enterprises overseeing a large fleet of trucks. When considering building an enclosed dock, consider some important considerations. For instance, enclosed docks should be spacious enough to park vehicles and adequately ventilated, and the layout should be simple and organized.

Depressed Dock

A depressed loading dock functions just like a flush dock. The main difference between these docks is that the depressed dock features a sloped driveway. Depressed loading docks are ideal for facilities with basement loading areas or separate dock levels. Instruct the vehicles to back in at an angle based on the driveway’s decline when using this loading dock.

Conclusion

Storage with loading dock is considered a crucial part of the distribution process. Different loading docks can be found in almost every other warehouse or distribution center. And knowing about them can help business owners determine which loading dock best fits their company’s needs. Moreover, consider different aspects, including the roadway approach, yard approach, landing strip, waiting area, etc., to design the loading dock’s layout.